German engineering with many years of experience

Our development department is located in our company building in Leutkirch im Allgäu.

Since 1995, we have been developing customised cooling solutions as well as standard products for electronic applications of all kinds. The R&D department staff have many years of experience in the design of thermal solutions. Specially trained employees who have been exclusively involved in the development of cooling solutions support our company tremendously. The daily cooperation with our production facilities in Asia and the annual on-site visits enable us to incorporate the most suitable manufacturing process with the best possible quality into our products.

In addition to the development and design of cooling solutions, our R&D department performs thermal simulations and measurements as well as feasibility tests and defines relevant measurement specifications.

Sustainability is very important to us

Sustainability is an important part of EKL AG's corporate philosophy. In cooperation with our suppliers and customers, we take economic considerations as well as ecological and social aspects into account in our decision-making processes. This enables us to further develop the performance of our products in a sustainable manner.

Conflict Minerals

In 2010, the United States Congress passed the Dodd-Frank Wall Street Reform and Consumer Protection Act (Dodd-Frank Act). Section 1502 of the Dodd-Frank Act and the implementing regulations of the U.S. Securities and Exchange Commission (SEC) require companies listed on the American stock exchange to report whether the products they produce or have contracted to produce contain "conflict minerals". The Dodd-Frank Act and the SEC define "conflict minerals" as tantalum, tin, tungsten (and the ores from which they are extracted) and gold.

The aim of this law is to prevent the use and trade of certain raw materials as well as human rights violations in the Democratic Republic of Congo and surrounding regions.

RoHS Directive

The aim of the RoHS Directive is to ban hazardous substances such as mercury, lead, hexavalent chromium, etc. from electrical waste. The fundamental condition for a partnership with EKL AG is that suppliers must comply with both the RoHS and the REACH directives. With the help of an X-ray fluorescence analysis, we also carry out random checks on our incoming goods.

REACH Regulation

The REACH regulation is an EU chemicals regulation and stands for Registration, Evaluation, Authorisation and Restriction of Chemicals. The main objective of REACH is to regulate the use of substances of very high concern. New SVHC are added to the candidate list twice a year. The list with the current 168 candidate substances can be found here.

Quality labratory with state-of-the-art measurement technology

We have greatly expanded our quality laboratory in recent years. In addition to a thermal rapid measuring device and a 3D measuring machine, we are also able to carry out X-ray fluorescence analyses.

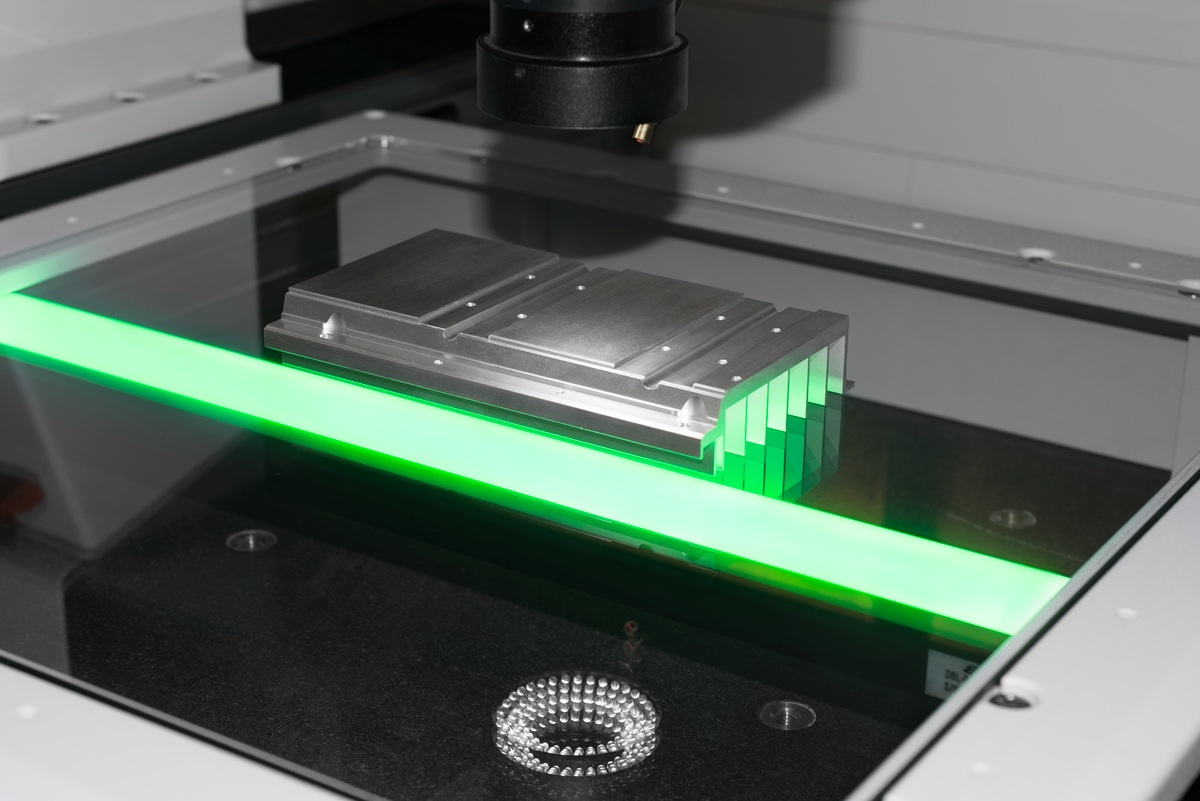

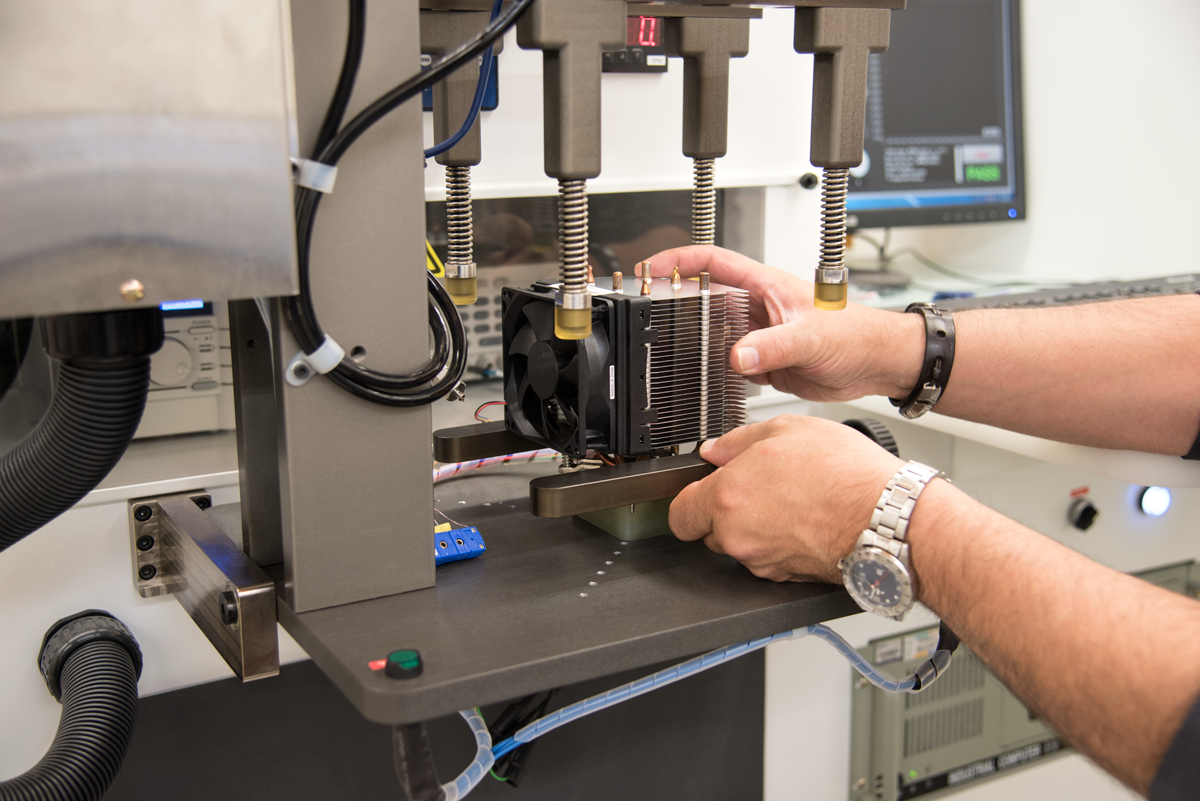

Rapid thermal measuring device

The rapid thermal measuring device allows comparisons to be made to the first samples / standard samples. In addition, position-related thermal tests can be carried out. This ensures that the products cool efficiently when installed.

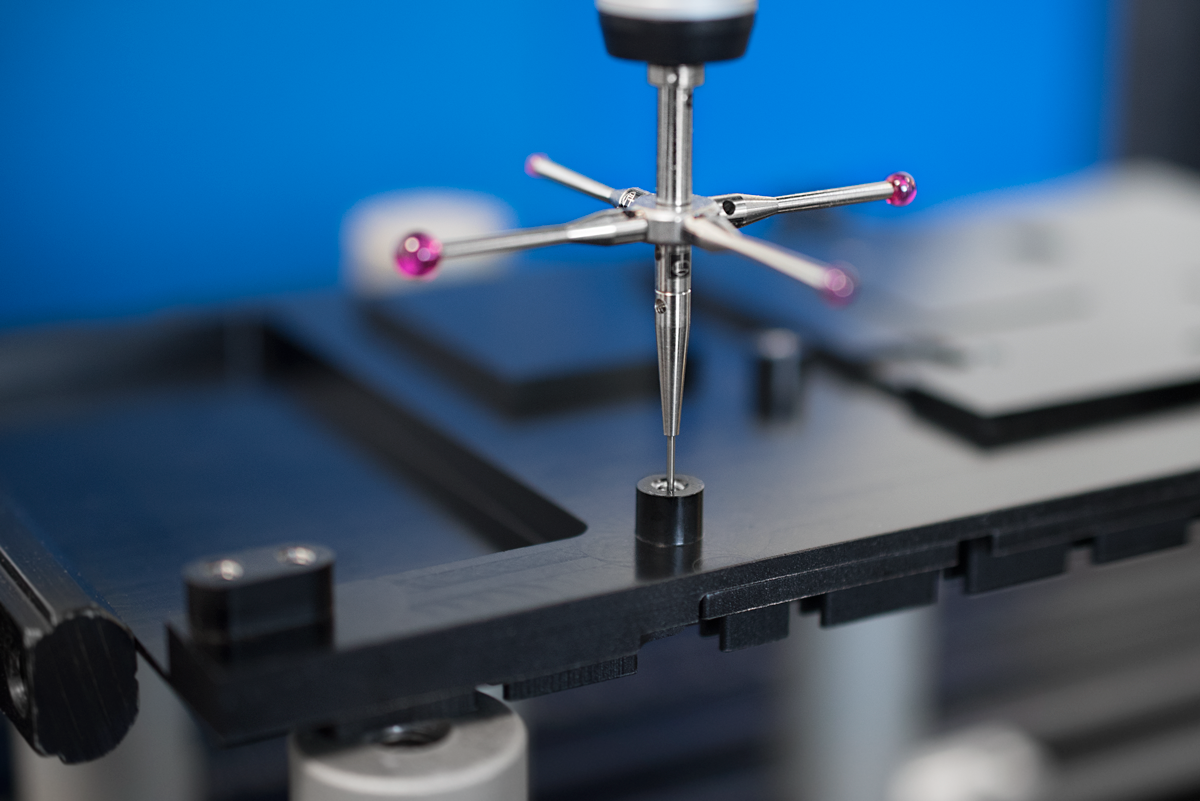

The 3D measuring machine allows products to be measured precisely.

Even customised products with very tight tolerances can be inspected down to 0.001 mm.

The measuring microscope supports us motorised with highly accurate, repeatable measurements of complex heat sinks of all materials. Starting from the manual 2-axis system up to the 3-axis system with automatic edge detection, the measuring microscope offers us various configurations of soft- and hardware for your specific measuring requirements.

X-ray fluorescence analysis

The X-ray fluorescence analysis is very important for us, as all our products are ROHS compliant. With the help of this device we can analyse components of the material and thus exclude non-permitted substances such as lead or mercury.

Wet-chemical analysis

For detailed analysis of non-homogeneous materials, we work together with certified testing laboratories.

Random inspection of all incoming goods

In order to ensure the consistently high quality of our products, we carry out extensive inspections of incoming goods for all deliveries in accordance with product-specific inspection plans or inspection specifications. In this way, we can intensify the testing of the critical features of your application. Test criteria include:

Visual inspection

During the visual inspection, the products are inspected for scratches, burrs, chips, workmanship, assembly, packaging, transport damage etc. Furthermore, we can individually inspect customer-specific cosmetic requirements for example for visible parts.

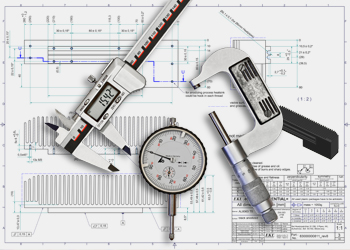

Dimensional inspection

With our extensive testing equipment, we are able to measure complex geometries accurately and repeatably. All function-relevant dimensions are tested, as well as threads, layer thickness, fits, etc.

Thermal testing

During thermal testing, the test samples are thermally measured in comparison to the defined initial samples or release samples. The test can be carried out in different installation positions, which is particularly important for coolers with heat pipes.

Electronic testing

Electronic testing of fans includes checking the polarity, speed, current consumption, tacho signal, PWM control, starting voltage and voltage range.

Assembly tests

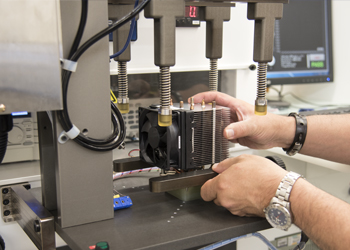

If an assembly test can be carried out by us, such as for CPU coolers on all common sockets, we carry out assembly tests with every delivery. This is to ensure that the contact pressure required by the CPU manufacturers is met. On request, we can also carry out assembly tests for customer-specific applications. For this, we only need a model of your application to integrate this into our test.

100% inspection according to customer specifications

Prototypes and initial samples are always 100% inspected in-house.

Upon customer request, we also carry out 100% inspections for small series as well as customised cooling solutions.

In this process, the customer specifies which test criterias (visual inspection, dimensional inspection, thermal inspection, electronic inspection and assembly test) are important. Following this, the customer receives a test report.

In-house CNC production and assembly

Our in-house production facility enables us to quickly and flexibly carry out reworking and to manufacture customised solutions.

CNC production

Sample production and prototyping, single-item to series production

In-house assembly of customised solutions

Cable assembly, assembly, customized solutions, assembly of subassemblies, reworking and repairs

We are DIN ISO 9001 certified

Our quality management, as well as that of our partners, complies with the standards of DIN EN ISO 9001.

The certificate and other certifications: