Simulate instead of trial and error

Constantly growing requirements and increasingly complex applications make well-considered preparation indispensable - especially in terms of optimising performance and costs in an ever more rapidly changing market.

By integrating thermal simulation into system development at an early stage, thermal problems can be identified and solved at an early stage. In addition, it is the most efficient way to visualise temperature developments and flow conditions. Ignoring thermal management may lead to the failure of a project in the worst case.

To help our customers reach their goals faster, we have greatly expanded our development department and further optimised our processes. We work with the simulation software FloEFD™ from the manufacturer Mentor Graphics, which is based on CFD methods. In combination with the latest hardware, we have high computing power to keep simulation times short.

Benefit from our experience

|

|

|

||

|

You have already designed a cooling solution and would like us to evaluate it professionally? |

You have a product that has reached its thermal and/or price limits and would like to optimise it? |

You are starting a new development and would like to have an optimised cooling solution developed at an early stage? |

||

Our range of services

Optimising your cooling solution

Suitable if you...

(by modifying the material or changing the fan type)

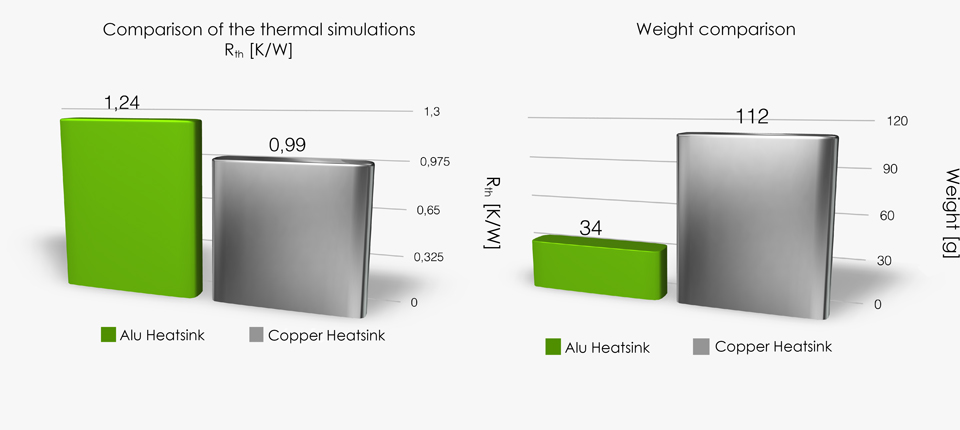

Example:

|

|

|

|

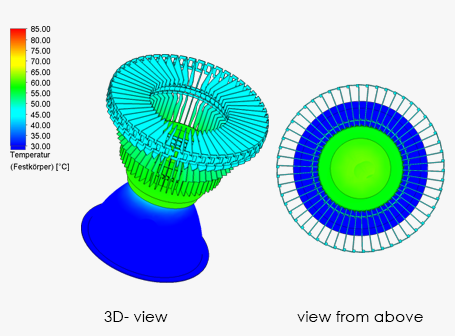

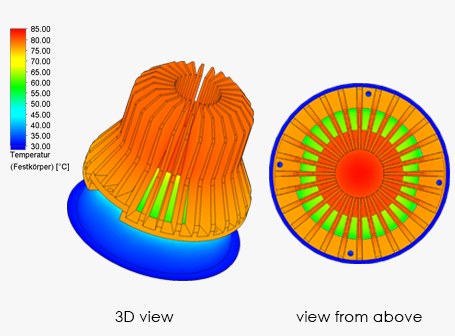

Simulation of aluminium heatsink

|

Simulation of copper heatsink

|

|

|

Note: The heat sink has a fan blowing through it, which is not shown in the simulation. |

||

Analysis:

Your advantages:

![]() Detection and elimination of thermal problems

Detection and elimination of thermal problems

![]() Possibility to vary materials / fans

Possibility to vary materials / fans

![]() Cost-optimised cooling solution

Cost-optimised cooling solution

Perfomance improvement for your cooling solution

Suitable if you...

(by changing the manufacturing technology, the material, the fan selection, etc.)

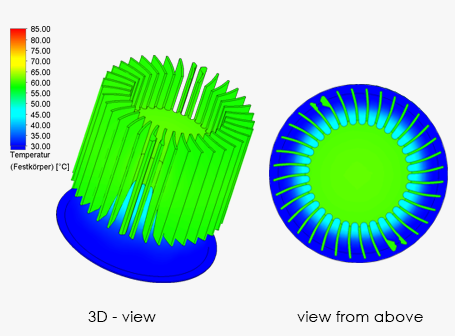

Example:

|

|

|

|

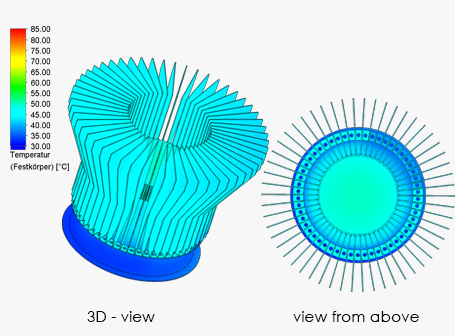

Simulation of die-cast heat sink

|

Simulation of extruded heat sink

|

|

|

|

|

|

|

Simulation soldered heat sink

|

Simulation of crimped heat sink

|

|

|

Note: The die-cast heat sink was the customer's initial product. The aim was to improve the cooling performance without a severe weight increase. |

||

Analysis:

Your advantages:

![]() Detection and elimination of thermal problems

Detection and elimination of thermal problems

![]() Performance and/or cost optimisation of your cooling solution without major development effort

Performance and/or cost optimisation of your cooling solution without major development effort

![]() Detection of HotSpots in your system

Detection of HotSpots in your system

![]() Identification of potential for improvements in the system design

Identification of potential for improvements in the system design

(e.g. size reduction at the same performance, arragement of components, size and number of ventilation slots in the housing)

New development of your cooling solution

Suitable if you...

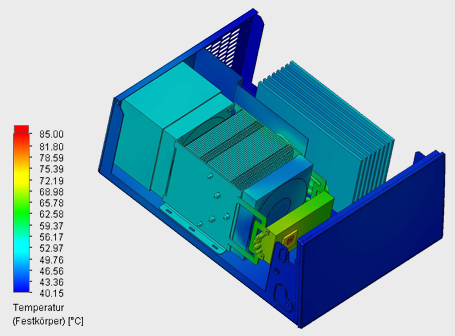

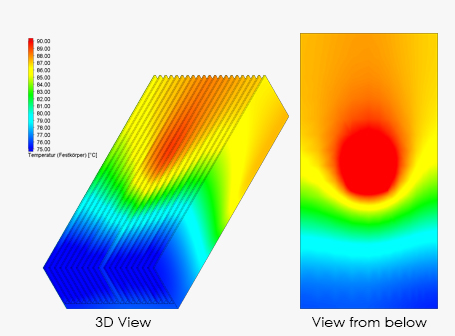

Example:

|

|

|

|

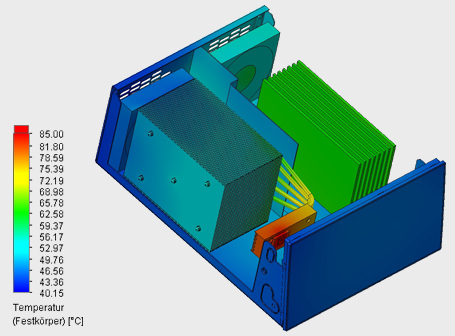

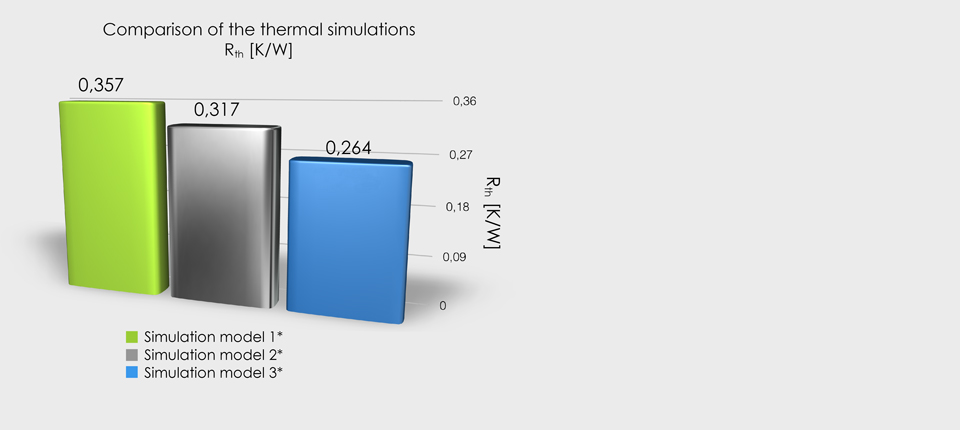

Simulation model 1*

|

Simulation model 2*

|

|

|

|

|

|

|

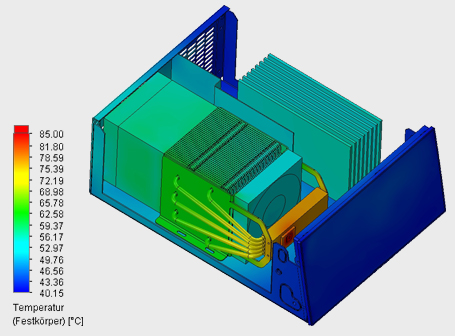

Simulation model 3*

|

|

|

|

Note: The customer had no cooling solution for his application yet. All models were designed by our engineering team. *Simulation model 1: - Large heat sink with long fins - One fan on the heatsink and an additional fan on the housing - 5 x 6 mm heatpipes (long heatpipes - decrease in performance) *Simulation model 2: - Shorter heat sink (less pressure loss) - The additional fan was now mounted on the heat sink - 5 x 6 mm heatpipes (shorter heatpipes - less decrease in performance) *Simulation model 3: - Shorter heat sink (less pressure loss) - The additional fan was now mounted on the heat sink - 2 x 6 mm heatpipes - 3 x 8 mm heatpipes |

||

Analysis:

Your advantages:

![]() Avoidance of thermal problems at an early stage

Avoidance of thermal problems at an early stage

![]() Significant time savings in development / less development loops

Significant time savings in development / less development loops

![]() Predictable development costs

Predictable development costs

![]() A shorter prototype phase

A shorter prototype phase

![]() Performance and cost-optimised cooling solution

Performance and cost-optimised cooling solution

![]() Detection of hotspots at an early stage

Detection of hotspots at an early stage

![]() Identification of further improvement potential during system design

Identification of further improvement potential during system design

(e.g. size reduction wit the same or higher performance, arrangement of components, size and number of ventilation slots in the housing)