Combining housing and cooling to create a holistic cooling concept

EKL develops custom heat sink housings

In a world where the power density of electronics is growing exponentially, efficiency and reliability are crucial to your commercial success. Conventional solutions often consider the cooling technologies in question separately from the housing design. EKL AG goes a decisive step further here:

We further develop your electronics housing from a thermal perspective to create a passive heatsink. The housing becomes an essential part of the cooling concept and contributes significantly to optimal heat distribution and convection. You benefit from our many years of experience and thermal simulations, which we can use to simulate almost any environmental condition. In this virtual development setting, we determine your individual cooling solution for your project in Germany and throughout Europe.

We further develop your electronics housing from a thermal perspective to create a passive heatsink. The housing becomes an essential part of the cooling concept and contributes significantly to optimal heat distribution and convection. You benefit from our many years of experience and thermal simulations, which we can use to simulate almost any environmental condition. In this virtual development setting, we determine your individual cooling solution for your project in Germany and throughout Europe.

Tailored thermal enclosure with optimum cost-benefit ratio

Standard housings quickly reach their limits - especially when thermal requirements increase or the design requires special features. Thanks to efficient development processes and moderate tool investments, customised solutions can often be realised faster and more cost-effectively than expected. You will be surprised at how few units it takes for the investment to pay for itself.

Request a quote now!

Request a quote now!

Advantages of heat sink enclosure

- Maximised efficiency: By eliminating with separate heat sinks and assembly steps, you can reduce process costs. An optimised cooling concept that incorporates the housing also extends the service life of expensive electronics.

- Unrivalled reliability: Passive heat sink housings are maintenance-free and fail-safe as they contain no moving parts such as fans that can wear out.

- Variety of combinations using different cooling technologies: If the heat source is not directly connected to the housing, we bypass the distances with heat pipes. By using heat pipes and vapour chambers, we achieve optimal heat distribution on the housing heat sink - with excellent results.

- Design freedom: The integration of the cooling function into the housing enables further miniaturisation and the realisation of unique, compact product designs.

- Process optimisation : Simplified assembly reduces cycle times in production and lowers the complexity of the bill of materials, contributing to a faster time to market.

Improving the performance of housing heat sinks by combining different technologies

Whether through air vents for improved convection, cooling fins to increase the surface area or complex systems such as heat pipes and vapour chambers for targeted heat distribution - our housing designs are engineered for maximized efficiency. Liquid cooling channels and individual combinations of different technologies also maximise the cooling performance of an housing heat sink.

Housing + air vents

Naturally occurring convection can be significantly improved by strategically placing air vents in enclosures. With the help of modern flow simulations, EKL develops housing shapes that guide the airflow efficiently and thus support heat dissipation - ideal for applications with limited space and without active cooling.

Housing + cooling fins/pins

Cooling fins and pins increase the surface area of the housing and thereby improve heat dissipation to the environment. EKL relies on precise design and thermal simulations to optimally adapt the geometry to the requirements of the respective application - for maximized efficiency with minimized material usage.

Housing + heatpipes

Heat pipes enable effective bypassing of larger distances between the heat source and the housing. EKL integrates this technology into housing to transport the heat in a targeted manner with low losses - particularly suitable for compact systems with physically separated components.

Housing + vapour chamber

Vapour chambers ensure an even distribution of heat across the entire surface of the housing. EKL uses this technology to prevent hotspots and reduce the thermal load on sensitive components - ideal for high-performance electronics with high packing density.

Housing + cooling channels

For applications with particularly high heat generation, EKL offers liquid-flow housings with integrated cooling channels. These enable fast and efficient heat dissipation and are customised to the customer's thermal requirements - perfect for industrial and high-performance applications.

Housing + any combination

EKL combines various cooling technologies to create customised all-in-one solutions. Whether air vents, fins, heat pipes, vapour chambers or liquid cooling - an intelligent combination results in a housing design that is prefectly tailored to the thermal and mechanical requirements.

Heat sink enclosures in practice: the right cooling concept for every product and application scenario

- Routers and gateways : For routers and gateways, which are often installed in narrow distribution cabinets or in rooms without air-conditioning, integrated cooling enables a higher power density in the smallest of spaces.

- HMI (Human Machine Interface): In automation, the passive housing heat sink protects sensitive electronics of HMIs from dirt and moisture, maximising reliability and service life in harsh environments.

- POS (Point of Sale) systems: A fanless, passively cooled enclosure for POS systems ensures quiet operation and minimises the risk of failures caused by dust and grease in retail environments.

- Industrial PC: The heat sink housing makes industrial PCs resistant to moisture and dirt, ensuring their functionality under harsh conditions.

- Rugged PC: Computers designed for use in extreme environmental conditions are predestined for a heat sink housing. Maintenance-free heat pipes or vapour chambers conduct the heat from the source to the housing, which protects the sensitive electronics from water and dust and shields them from temperature fluctuations and vibrations.

- Mini PC: The integration of the housing into the heat sink concept allows the design of extremely compact mini PCs that offer high computing power within the smallest dimensions.

- Edge computing : Processing data directly at the point of action - as with sensors, machines, vehicles, IoT (Internet of Things) - requires maintenance-free cooled electronics. The dual use of the housing as a heat sink provides large convection surfaces for heat dissipation.

- Measuring devices: Precision measuring devices benefit from fanless housing cooling, which minimises interference from vibrations or air currents, thereby increasing the accuracy and repeatability of measurement results.

- Control cabinet components: When cooling power electronics in data cabinets or industrial control cabinets, the thermally optimised housing as a heat sink, enabling a high packing density. In some cases, active fans are not necessary, which simplifies maintenance and increases the reliability of the entire server cabinet.

- DIN rail components: Electronics mounted on a DIN rail (also known as a "top-hat rail") - such as industrial PCs, switches, power supply units, routers, frequency converters - dissipate heat to the inside enclosure via their housing. The control cabinet is cooled via the housing and/or actively by fans.

- Wallboxes : In charging stations for electric vehicles, robust, passive cooling ensures reliable heat dissipation from the power electronics, which must function flawlessly perfectly in all weather conditions.

- Embedded systems: The housing acts as a heat sink, enabling the design of extremely compact and hermetically sealed embedded systems that can be used in sensitive or dusty areas (e.g. medical technology or food production) and increase design freedom.

- LED floodlight systems: For high-performance LED floodlight systems in sports and event venues, the housing acts as a heat sink, ensuring that the LEDs operate at an ideal temperature, which drastically extends their service life.

- Surveillance technology: In outdoor cameras or sensors, the housing not only protects the electronics from the effects of the weather, but also ensures reliable heat dissipation without the need for additional space for active cooling systems.

EKL: Expertise in thermal management that perfects your housing design

Our strength lies in our profound technical expertise in designing the best possible and most cost-effective electronic cooling system for your project from a wide range of available manufacturing processes and products.

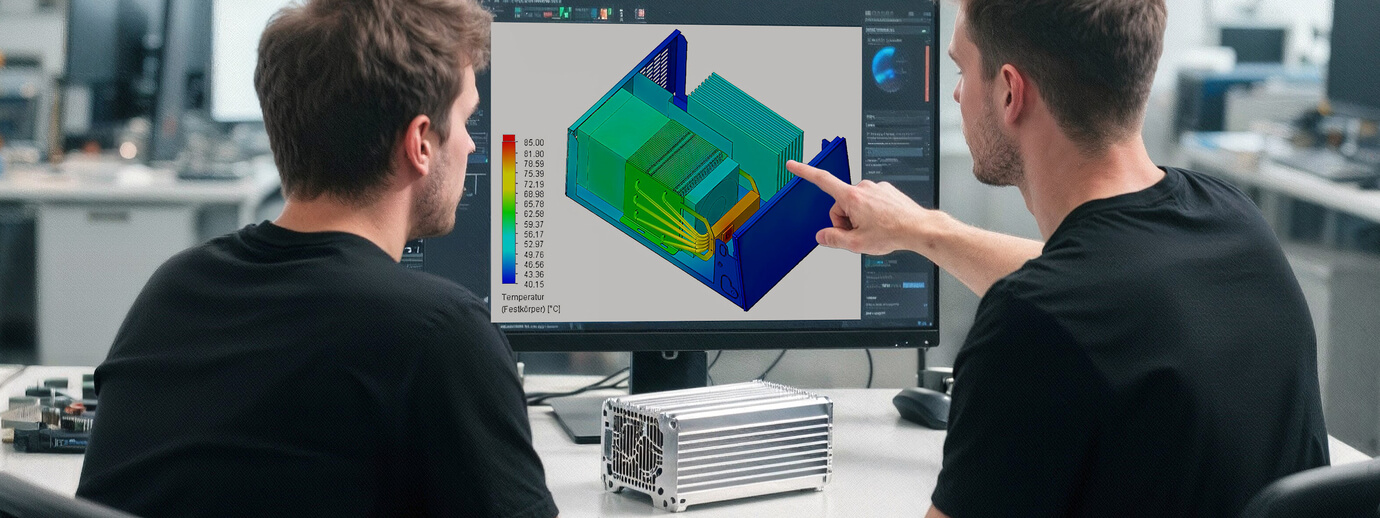

Computer-aided simulations using FEA (finite element analysis) and CFD (computational fluid dynamics) enable us to simulate and optimise the thermal behaviour of your product as early as the design phase. Based on the many years of experience of our employees, we run through promising variations of cooling technologies, heat sinks, materials and housing arrangements. Without any material consumption and production costs, but with valid measurement data and results, we determine your individual cooling solution with the best cost-performance ratio for your production. This simulation data is later verified with thermography on near-series prototypes under realistic conditions.

Computer-aided simulations using FEA (finite element analysis) and CFD (computational fluid dynamics) enable us to simulate and optimise the thermal behaviour of your product as early as the design phase. Based on the many years of experience of our employees, we run through promising variations of cooling technologies, heat sinks, materials and housing arrangements. Without any material consumption and production costs, but with valid measurement data and results, we determine your individual cooling solution with the best cost-performance ratio for your production. This simulation data is later verified with thermography on near-series prototypes under realistic conditions.

Practical examples: Housing heat sinks in action

Heat dissipation via the housing is used in electronic components in various high-tech industries:

Medical technology

In ultrasonic devices or laboratory analysers, quiet, fanless cooling ensures maximum patient comfort and sterility. Decision-makers benefit from increased device service life and minimised maintenance costs.

Renewable energies

In inverters in photovoltaic systems or control electronics in wind turbines, the robust, maintenance-free housing acts as a heat sink ensuring maximum uptime and efficiency.

LED lighting technology

In industrial or street lighting, housing cooling prevents overheating, which drastically shortens the service life of the LEDs. This significantly reduces the total cost of ownership (TCO).

Housing as heat sink for IPC electronics

Embedded hardware enclosures can be made from materials such as steel, aluminium, galvanised steel or stainless steel to enable efficient cooling. Metals conduct heat well and distribute it across the entire surface of the enclosure. Metal enclosures also provide good protection for your embedded systems against electromagnetic interference.

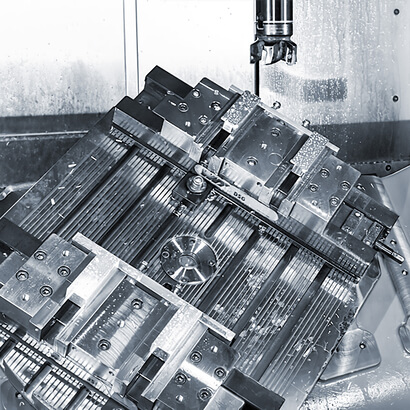

Die-cast aluminium heat sinks in particular can also serve as housings. Complex geometries can be realised in almost any size using this manufacturing process. Handles and mounting elements can be integrated into the die-cast design. This reduces the time and effort involved in assembly and post-processing your HMI displays / POS displays.

Die-cast aluminium heat sinks in particular can also serve as housings. Complex geometries can be realised in almost any size using this manufacturing process. Handles and mounting elements can be integrated into the die-cast design. This reduces the time and effort involved in assembly and post-processing your HMI displays / POS displays.

FAQ about heat dissipation via housing

Is enclosure cooling as efficient as a heat sink with a fan?

In many applications, especially in environments that require silent or fanless cooling, passive enclosure cooling is the most efficient and reliable solution. We optimise the enclosure geometry to ensure maximum heat dissipation without moving parts.

What materials are used for the housing cooling?

Mainly highly thermally conductive aluminium alloys. For particularly high power densities, copper inserts or other composite materials can also be integrated in order to dissipate the heat to the housing in a targeted manner. To dissipate power loss over distances to the housing, we use heat pipes or vapour chambers on the component inside the housing.

How is the connection between the electronics and the housing made?

If the heat source can be connected directly to the housing, the heat is dissipated via various thermal interface materials (TIMs), such as thermal conductive foils, pastes or pads, which ensure optimum heat transfer from the electronic components to the housing. Over "long" distances, heat pipes are a highly efficient and maintenance-free technology for heat transfer.

Can the housing also perform mechanical functions?

Absolutely. The housing heat sink not only protects the electronics, but can also integrate mounting points, seals for IP protection classes and interfaces for external connections, reducing the complexity of the overall assembly.

Request a quote now!

EKL AG supports you from the initial idea through thermal simulation to cost-efficient series production. Our engineers work closely with your teams to find a solution that is not only technically convincing, but also achieves your financial and operational goals.

Are you ready to redefine the efficiency and reliability of your electronics?

Request a free initial consultation with our thermal management experts now and receive a non-binding quote.

Are you ready to redefine the efficiency and reliability of your electronics?

Request a free initial consultation with our thermal management experts now and receive a non-binding quote.

Let's talk about your cooling task! Which manufacturing processes for your cooling solution?

Put your trust in EKL's experience and expertise: we offer development, design, thermal simulation, prototyping and selection of the manufacturing processes with the best cost-benefit ratio. Let's talk about:

Frank Sichler

Sales Manager

+49 (0)7561 9837-47

f.sichler@ekl-ag.de

Make an appointment Send request by e-mail

Put your trust in EKL's experience and expertise: we offer development, design, thermal simulation, prototyping and selection of the manufacturing processes with the best cost-benefit ratio. Let's talk about:

Frank Sichler

Sales Manager

+49 (0)7561 9837-47

f.sichler@ekl-ag.de

Make an appointment Send request by e-mail